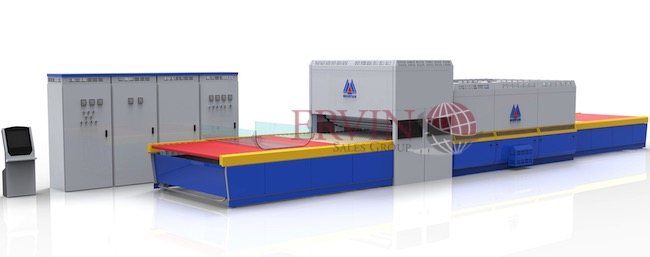

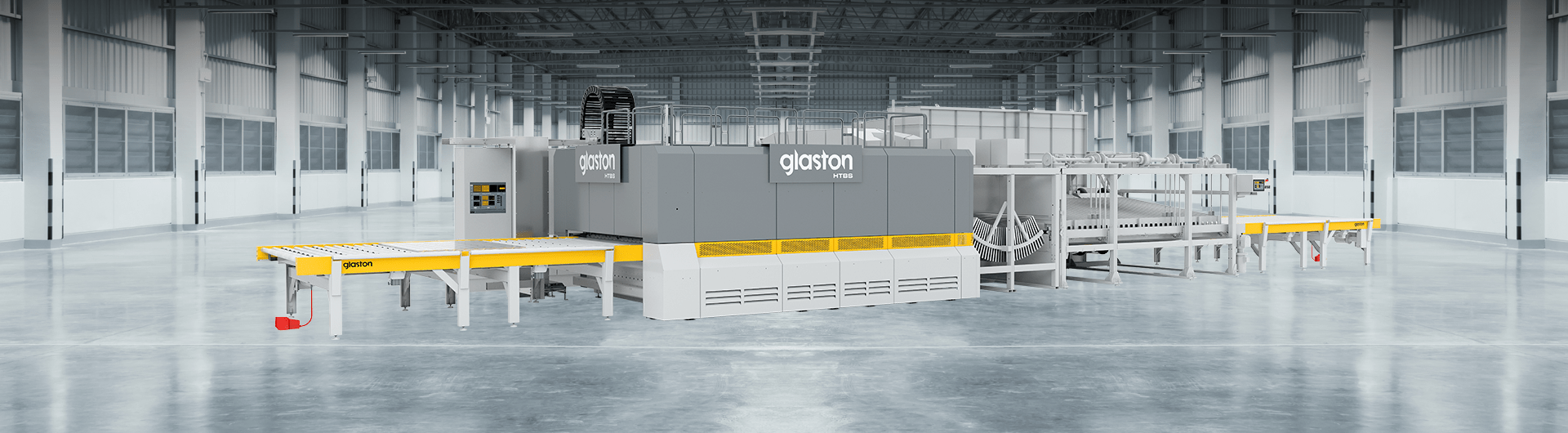

Glass Sheet Bending Furnace

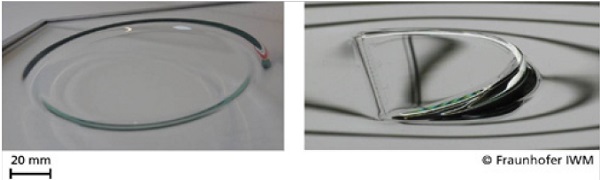

The glass nestles to the hoop and get the favored form.

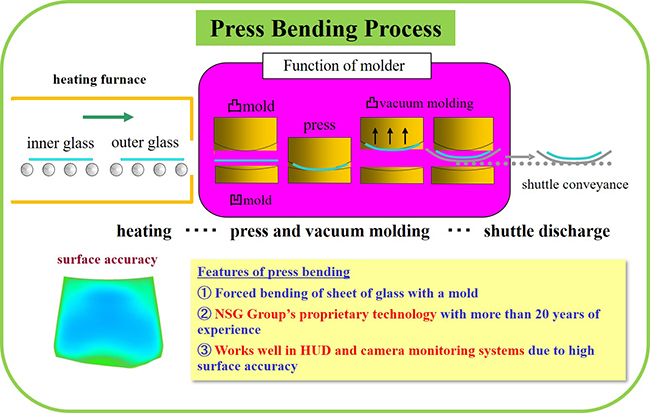

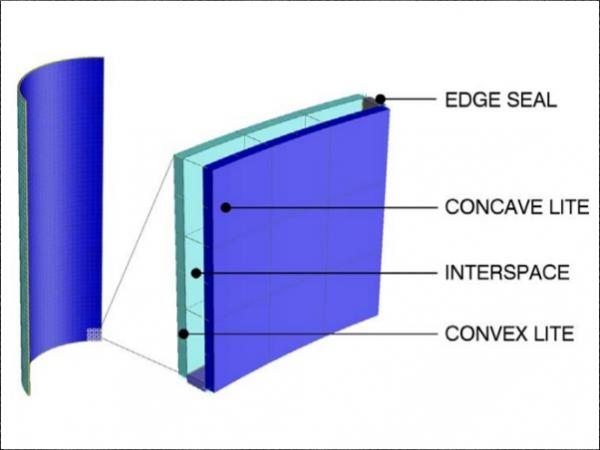

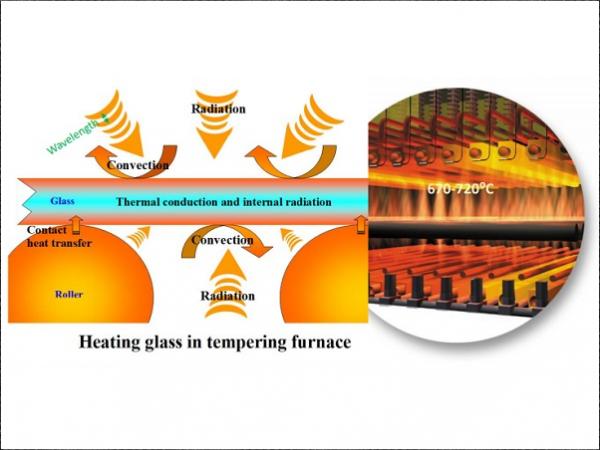

Glass sheet bending furnace. A first group of a plurality of heating elements are fixed on an inner. The bending mold is continuously conveyed through a heating furnace where the glass sheet is heated to its deformation temperature until the glass sheet begins to deflect under gravity and conform to the shape of the forming rail. Glass bending furnace ir heating of foundary sand moulds a sheet glass float glass can be hot worked at about 600 to 800ºc and can be given very attractive shapes and forms like bending slumping and fusing to produce varieties of decorative articles which are eye catching in interior decoration in homes hotels and show rooms. A wide variety of glass bending furnace options are available to you such as key selling points machine type and condition.

The glass panes are put on the hoop and then heated in the bending furnace. The infrared line camera pyroline camera made by dias can be used to monitor the glass temperature at the exit of a rotary furnace just prior to the bending press. About 27 of these are glass processing machinery 0 are industrial furnace and 0 are heating equipment. A7 glass bending furnace this glass bending furnace is designed to create j and r shaped tempered glass and is ideal for bus side windows shower stalls architectural applications furniture appliances and more.