General Tolerance Sheet Metal Thickness

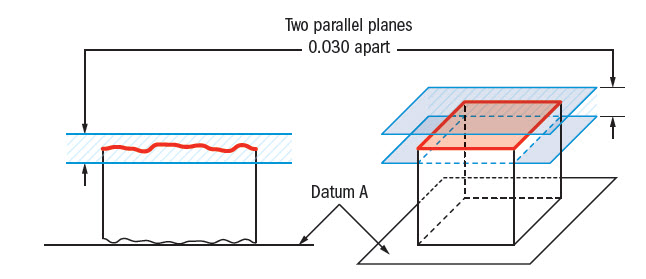

2 the flatness tolerances only apply to sheet and plate.

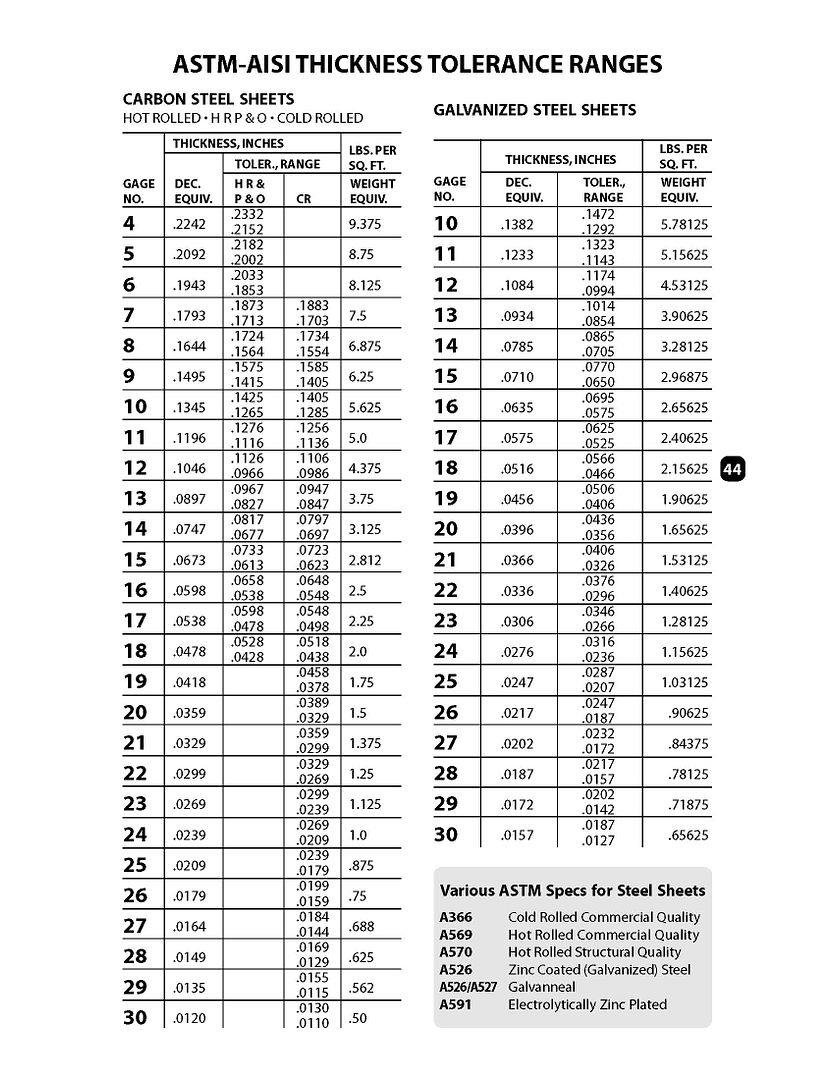

General tolerance sheet metal thickness. Galvanized sheet thickness tolerances thickness in inches weight thickness in millimeters gage min. Thicknesses can vary significantly. As per design requirements and manufacturing capability tolerance class is defined. This level of accuracy would generally be unachievable by the metal producer.

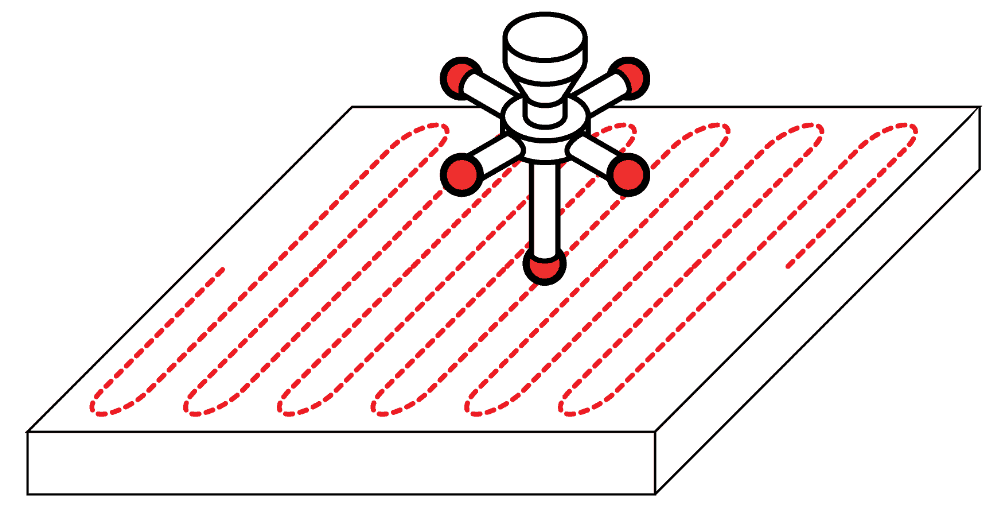

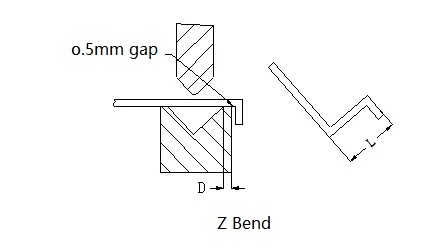

In the above example m and k has defined the tolerance. For sheet metal parts iso 27 68 mk is used. During the rolling process the rollers bow slightly which results in the sheets being thinner on the edges. Over 6 to 30 incl.

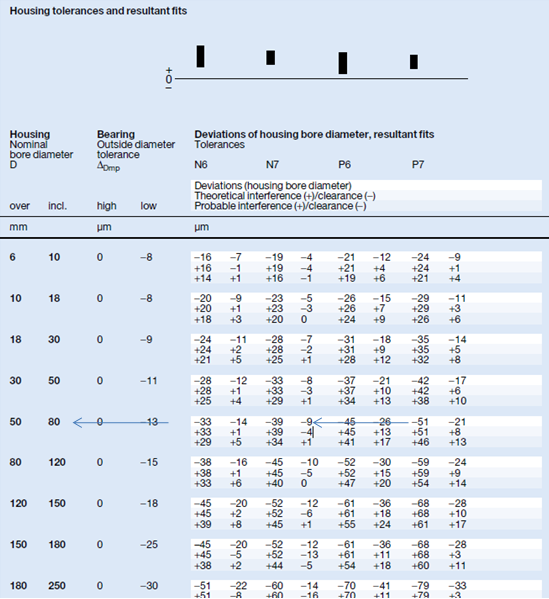

General dimensional tolerance of blanking unit mm 1. Extremely thin sheets are considered foil or leaf and pieces thicker than 6 mm 0 25 in are considered. Standard specification for general requirements for sheet steel metallic coated by the hot dip process formerly astma525. Category b c d tolerances on normal flatness mm thickness mm width mm category b category c category d th 25 00 w 1200 18 23 1200 w 1500 23 30 after prior agreement w 1500 28 38 2 the flatness tolerances only apply to sheet and plate.

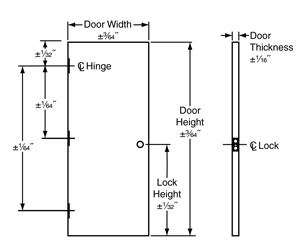

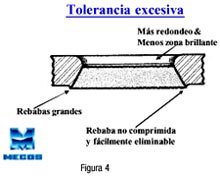

6 or less note grade a b and c are equal to tolerance. Without a specified tolerance this could mean the purchaser wants a metal sheet that is 48 00000000 inches by 96 00000000 inches. The sheet metal does however have a tolerance on the rolling thickness which needs to be taken into account when designing a tight fitting assembly especially as the sheet metal material gets thicker. Unlike the old standards these tolerances apply for any length that can be supplied and across the whole thickness range.

General tolerance iso 2768 does not specify where to use these tolerances. Each range is proportional to the length of the sheet or cut length with a minimum tolerance at 2000mm length. Iso 2768 is mainly for parts that are manufactured by way of machining or removal of materials. All tolerance limits are given in mm.

Over 120 to 400 incl. Sheet metal is metal formed by an industrial process into thin flat pieces. Sheet metal guage tolerances. Special tolerance should be specifically requested.

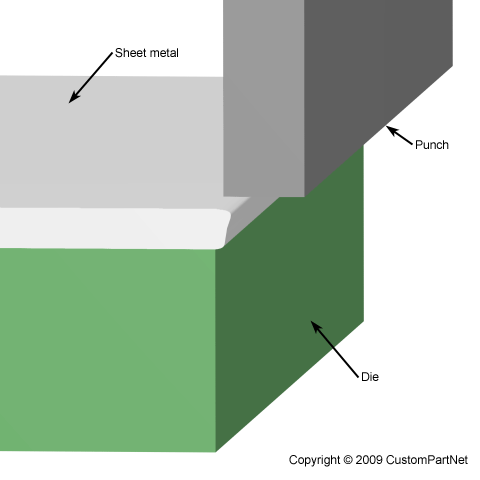

Over 30 to 120 incl. And for machined components iso 27 68 fh can be used. Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes countless everyday objects are fabricated from sheet metal. And astma653 a653m 94 standard specification for sheet steel zinc coat.

The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the manufacturer s standard gauge which has no inherent tolerances. Over 400 to 1000 incl.