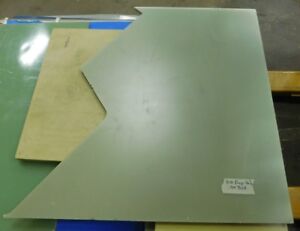

Garolite G10 Industrial Strength Fiberglass Sheets

Therefore fr4 can be safely substituted where g10 is called for while g10 can never be substituted where fr4 is called for.

Garolite g10 industrial strength fiberglass sheets. Use these garolite g 10 sheets and bars in place of garolite g 10 fr4 for applications that are sensitive to halogen such as in nuclear plants. F for flame and r for retardancies and the 4 is a 4 epoxy. G10 fr4 aka garolite g10 sheets mil i 24768 27. G10 meets mil i 24768 2 gee and fr4 meets mil i 24768 27 gee f.

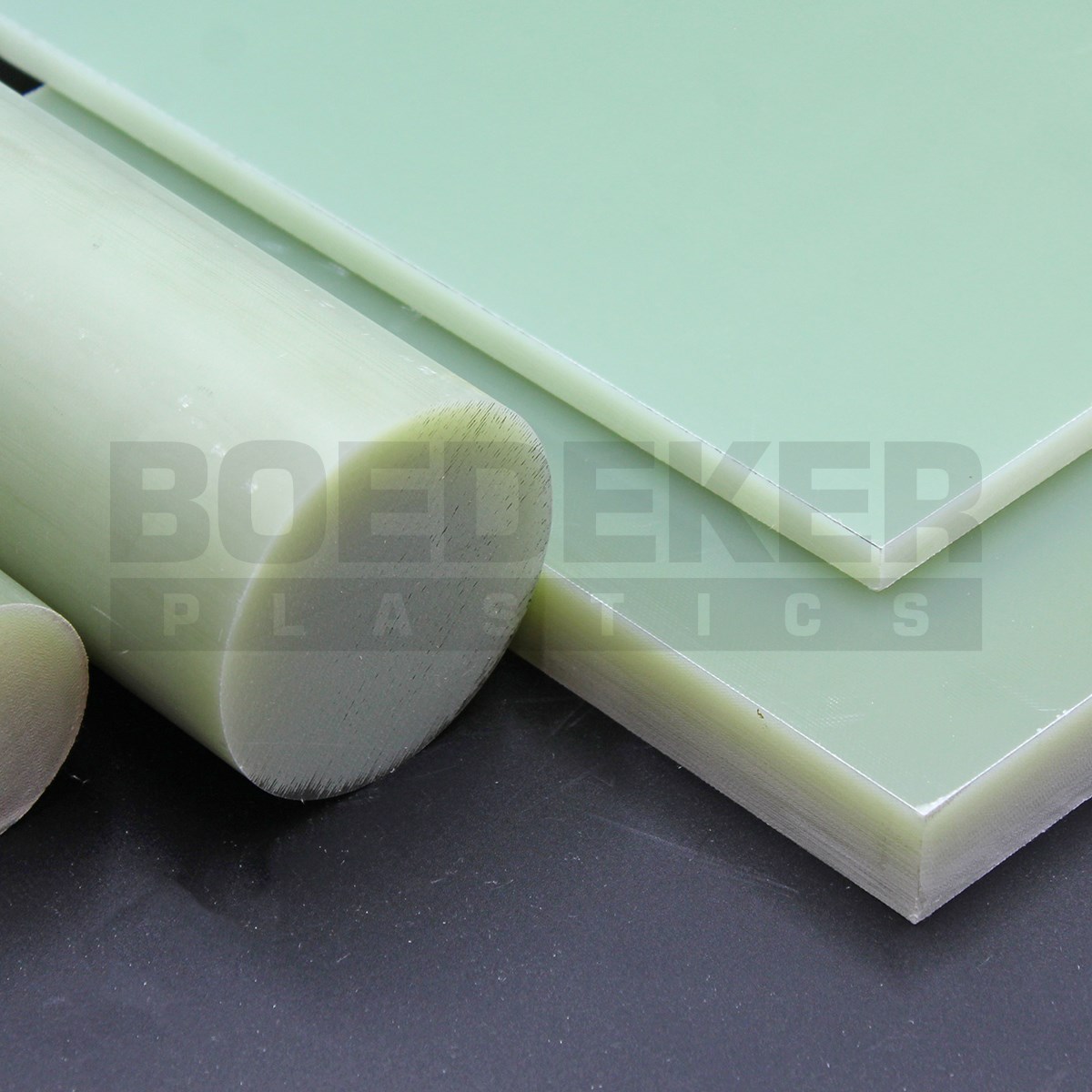

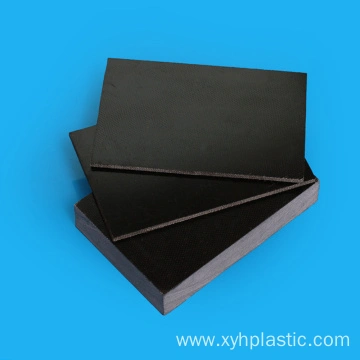

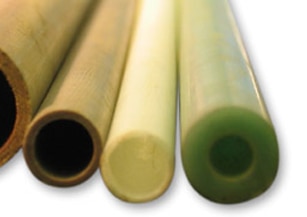

Phenolic g 10 fr4 is a continuous woven glass fabric laminated with an epoxy resin. Made of an epoxy resin with fiberglass fabric reinforcement garolite g 11 is sometimes called epoxy grade industrial laminate and phenolic. The abbreviation fr4 means. A good all around choice these garolite g 10 fr4 sheets and bars are strong machinable and electrically insulating.

G10 fr4 fr4 is a fire rated electrical grade dielectric fiberglass laminate epoxy resin system combined with a glass fabric substrate. This grade is extremely high in mechanical strength has low water absorption and dissipation factors and has superior electrical characteristics which are exhibited over a wide range of temperatures and humidities. Garolite g 10 fr4 is also called epoxy grade industrial laminate and phenolic. G10 fr4 fr4 is a fire rated electrical grade dielectric made with and epoxy material reinforced with a woven fiberglass mat.

Overview of g 10 fr 4 sheets g 10 fr 4 is a thermosetting industrial laminate consisting of a continuous filament glass cloth material with an epoxy resin binder. Grade g 10 garolite sheet stock. Made of an epoxy resin with fiberglass fabric reinforcement garolite g 10 is also called epoxy grade industrial laminate and phenolic. Foam sheets damper convertible low carbon steel sheets decorative metal sheets drop sheets dry erase sheets e glass grade garolite sheets electrical grade fiberglass gpo3 sheets emery sheets etched sheets.

Fr 4 is an abbreviation for flame resistant 4. Fr 4 is commonly used in printed circuit boards. Garolite has electrical insulating properties which are useful for electronic integrations. They re strong machinable and electrically insulating.

Garolite g 10 or g10 is a composite material created by curing fiberglass and epoxy under high pressures. The main difference between nema grades g10 and fr4 is that fr4 is a fire retardant grade of g10. Offering higher strength and better heat resistance than garolite g 10 fr4 sheets these garolite g 11 sheets are suitable for continuous use in elevated temperatures they retain at least 50 of their structural strength at temperatures above 300 f.

.jpg)