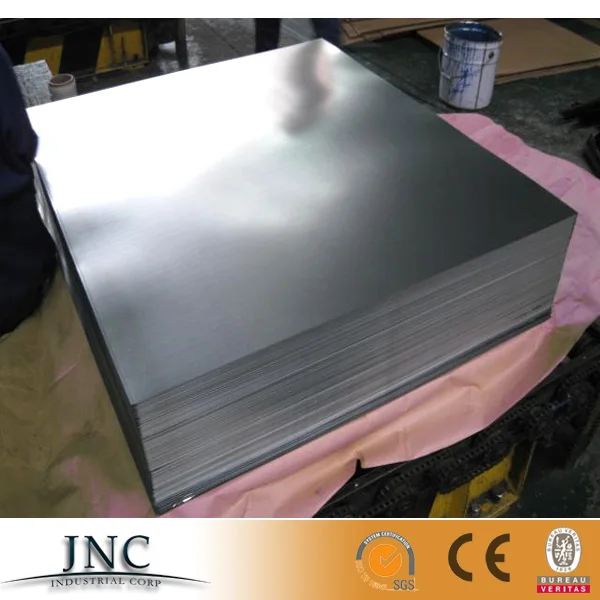

Galvanized Steel Sheet Electrolysis

A lower cost alternative to stainless steel galvanized sheet and plates have a rust free protection for up to 30 years while maintaining strength with a durable surface coating.

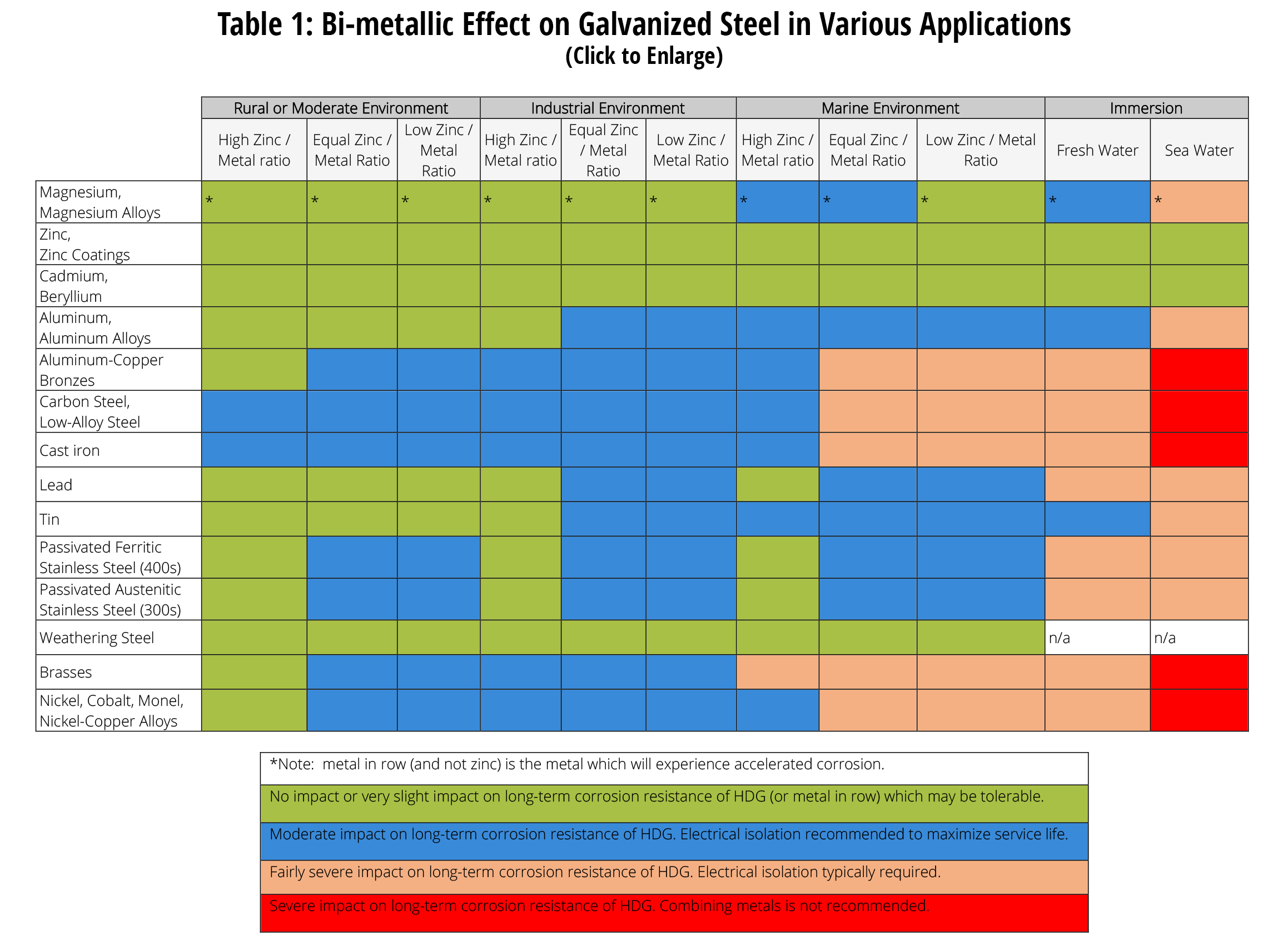

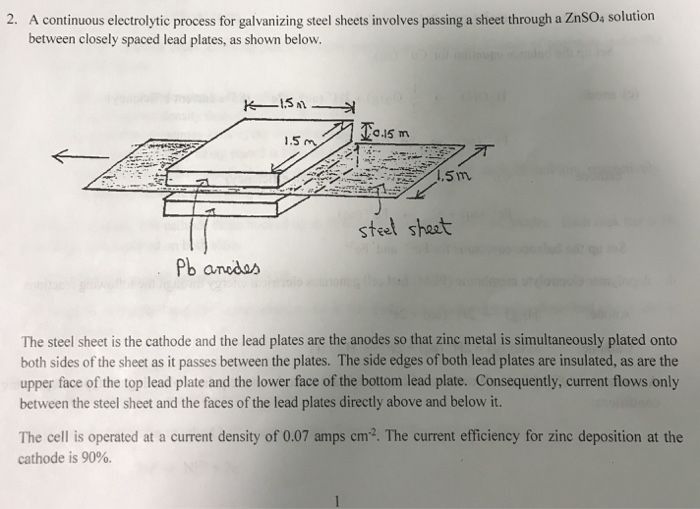

Galvanized steel sheet electrolysis. The presence of two dissimilar metals in an assembly is not always a sign of trouble but it could be a problem. Hot dip galvanized steel is well suited for use in a variety of environments and fabrications and sometimes is placed in contact with different metals including among others stainless steel aluminum copper and weathering steel. Galvanized steel sheet plates are intended for use where greater corrosion protection is required without painting. Galvanized steel also can be coated with nickel copper etc.

This is not to say that no form of corrosion will ever occur though. Stainless steel and galvanized materials often are found together in the industry with applications such as galvanized fasteners stainless steel pressure vessels and roof and siding panels. If you break the conductive metal circuit between the copper and galvanized pipe galvanic corrosion electrolysis does not occur. Galvanic corrosion also called bimetallic corrosion or dissimilar metal corrosion is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another in the presence of an electrolyte.